Hydrogen Fuel Cell (Bruin Racing Supermileage)

- Bruin Racing Supermileage is a student-led team at UCLA that designs and manufactures fuel efficient vehicles. For these past few years, our team has been using hydrogen as our fuel source due to its renewability and because it does not produce any greenhouse gases. Currently, our team is working on creating the hydrogen fuel cell that will power our vehicle. While there are many components that go into the design of a hydrogen fuel cell, I have mostly been working on the hardware and architecture of the fuel cell. This includes, the flow field plates, end plates, gaskets, and current collectors.

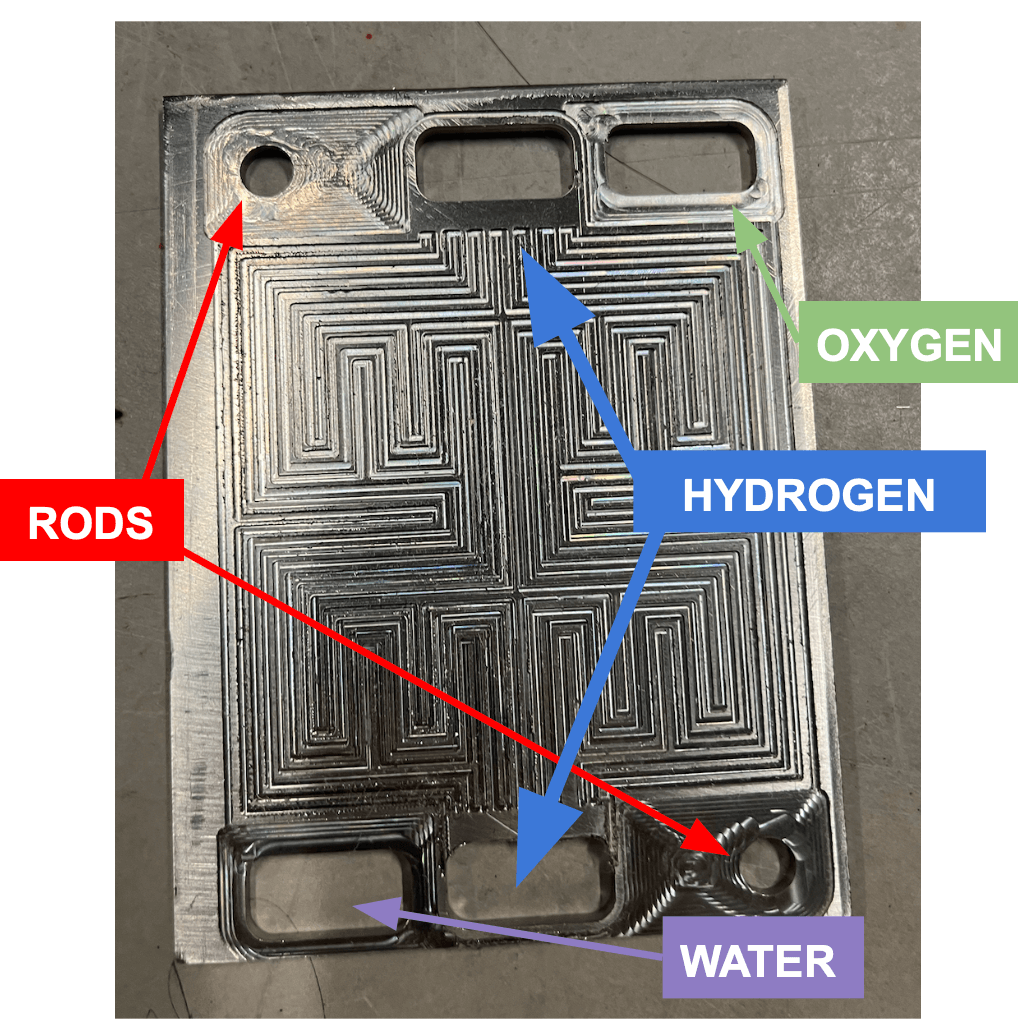

- Flow Field Plates: this stainless steal plate features groves along its surface. These grooves take in hydrogen. As the hydrogen flows along these grooves, hydrogen will pass through the membrane electrode assembly (MEA). Our flow field plates feature oxygen and hydrogen intake channels. Excess hydrogen will leave through another channel. As oxygen enters, it will combine with the hydrogen to create water vapor that then exits through another channel. We also included holes for rods that will help us assemble the fuel cell when all the parts are complete. These plates were created using CNC machines. One problem we ran into was that making these plates was very difficult becuase the channels are very small and the end mills we were using were very small. This meant that the end mill would break very easily and we ended up using about 20 end mills to create our flow field plate. We need to create 50 of these flow field plates so were are currently looking at other options to manufacure these plates.

- Gaskets: we are still doing research on this, but we plan to use EDPM rubber.

- Current Collectors: we are still doing research on this, but we plan to use copper.

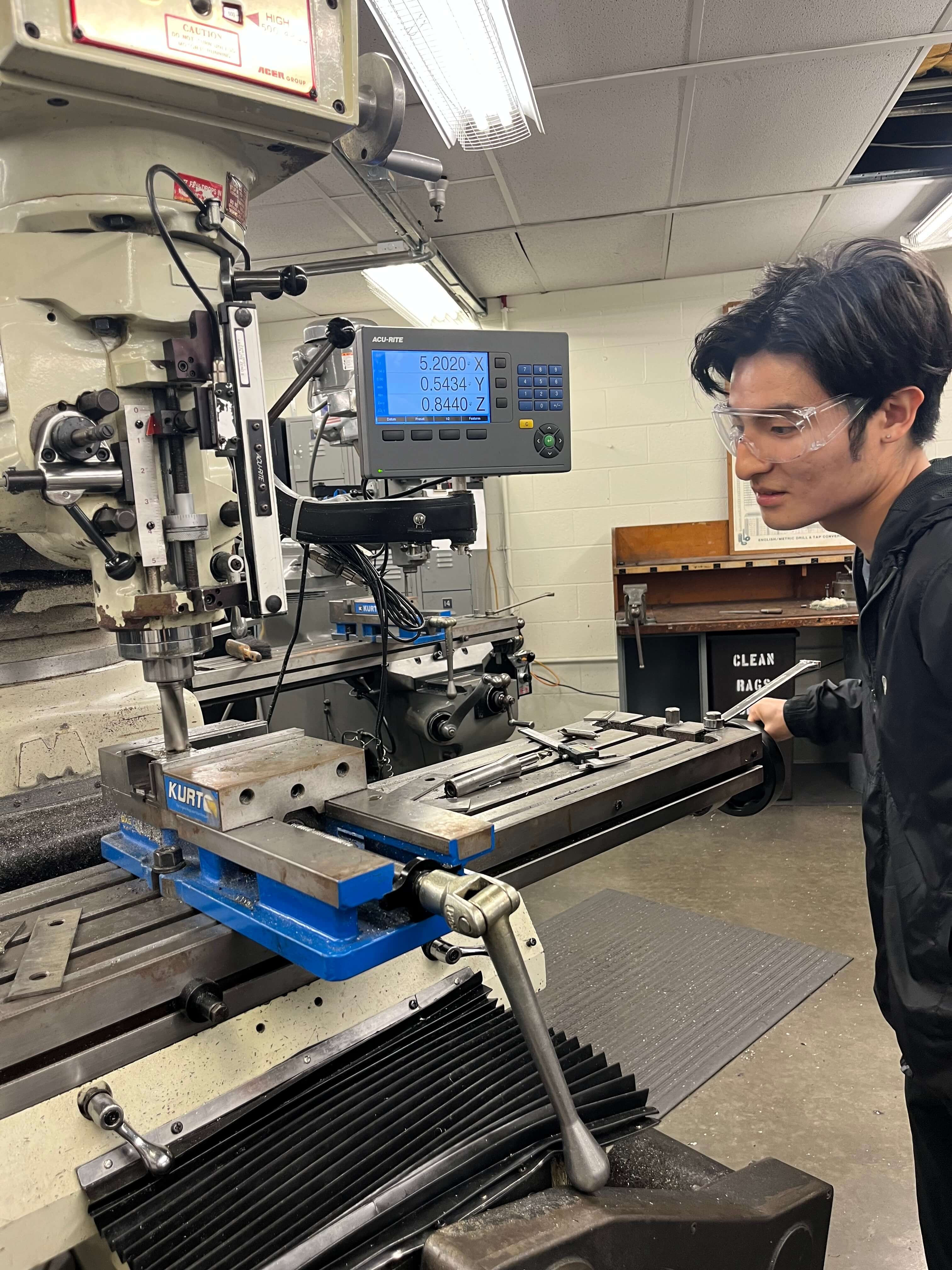

- Takeaways: This fuel cell is close to completion and we just need to pick final designs and manufacure. Currently, our team is trying to create a smaller fuel cell, so we're trying to manually mill a flow field plate and we are soon going to see if we can get it to create some power. This was a good learning experience for manufacturing techniques such as CNC and milling. I really enjoyed seeing my CAM come to life.